The National Robotarium work experience programme inspires budding roboticists

The National Robotarium has launched a new work experience programme for secondary schools.

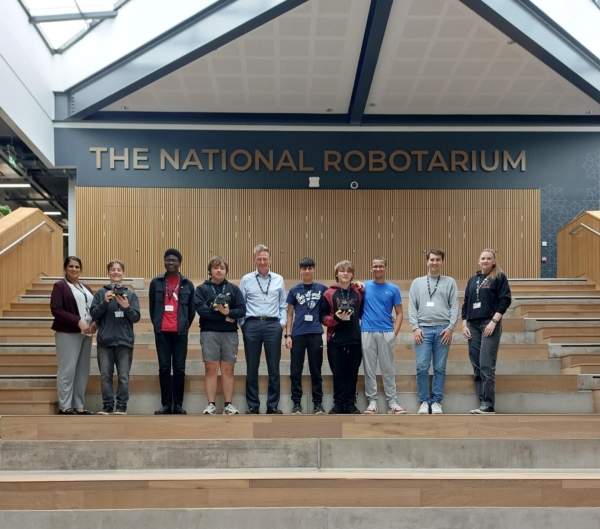

Overseen by Schools Engagement Lead (and former Computer Science teacher), Sabaht Bashir, the immersive week-long programme ran from 9-13 June 2025, offering a glimpse behind-the-scenes at the UK’s centre for robotics innovation.

The group, made-up of young people from schools across Scotland and England, kicked-off the week with a tour the facility’s high-spec labs and workshops, and the wider Heriot-Watt campus, taking in its vast green spaces and multi-million pound Oriam Sports Centre.

They learned about the different roles undertaken at the facility, ranging from Robotics Engineers and Technicians to Project Management and Marketing and Communications, as well as the different pathways to robotics careers, including Heriot-Watt University’s Graduate Apprenticeship scheme.

They also got hands-on experience operating some of the robotic technologies being developed for research and industry partners, such as the Boston Dynamics Spot robot dogs, as well as interacting with social engagement humanoid Ameca, and building their own robotic cars with the help of Senior Robotics Engineer Ronnie Smith. On the final day, members of the National Robotarium Leadership team judged their efforts during a presentation showcase in the main Atrium space.

Work experience participants with School Engagement Lead Sabaht Bashir, COO Steve Maclaren, Robotics Engineer Ronnie Smith, and Project Manager Rowanne Miller

Callum Samson, a 4th year pupil from St John’s RC High School in Dundee, was one of the participants. He said: “I really enjoyed work experience at the Robotarium – the members of staff were all really friendly. I was really surprised at how big the centre is, with lots of different jobs that are really interesting.

“Spending a week at The National Robotarium has changed my perceptions of robots and their levels of advancement. There are lots of different robots for different tasks however they need a lot of support and programming by humans to undertake these.

“I’ve really enjoyed my time here and definitely would like to come back when I’m older to study or work.”

Jakub Przybek from St Modan’s High School said: “Visiting The National Robotarium for work experience has opened my eyes to a whole new world of integrated robotics in so many different sectors.

“I’ve found robots can be used for every type of industry and aren’t just limited to mechanical or manufacturing tasks.

“I’d love to become a Robotics Engineer at the Robotarium when I’m older!”

Other participants in the group were Ben Lake, George Heriot’s, Manuel Amadiegwu, Dartford Grammar School, Alex Vynnytskyi, St Modan’s, Jamie Stephenson, The Priory Academy LSST, Daniel Gregor, Boroughmuir HS, and Alex Florea and Oakley Dow, both St Kentigerns Academy.

Want to know more about The National Robotarium’s work experience programme? Contact s.bashir@hw.ac.uk for information on 2025/26 opportunities.

Chris Barron

Chris Barron